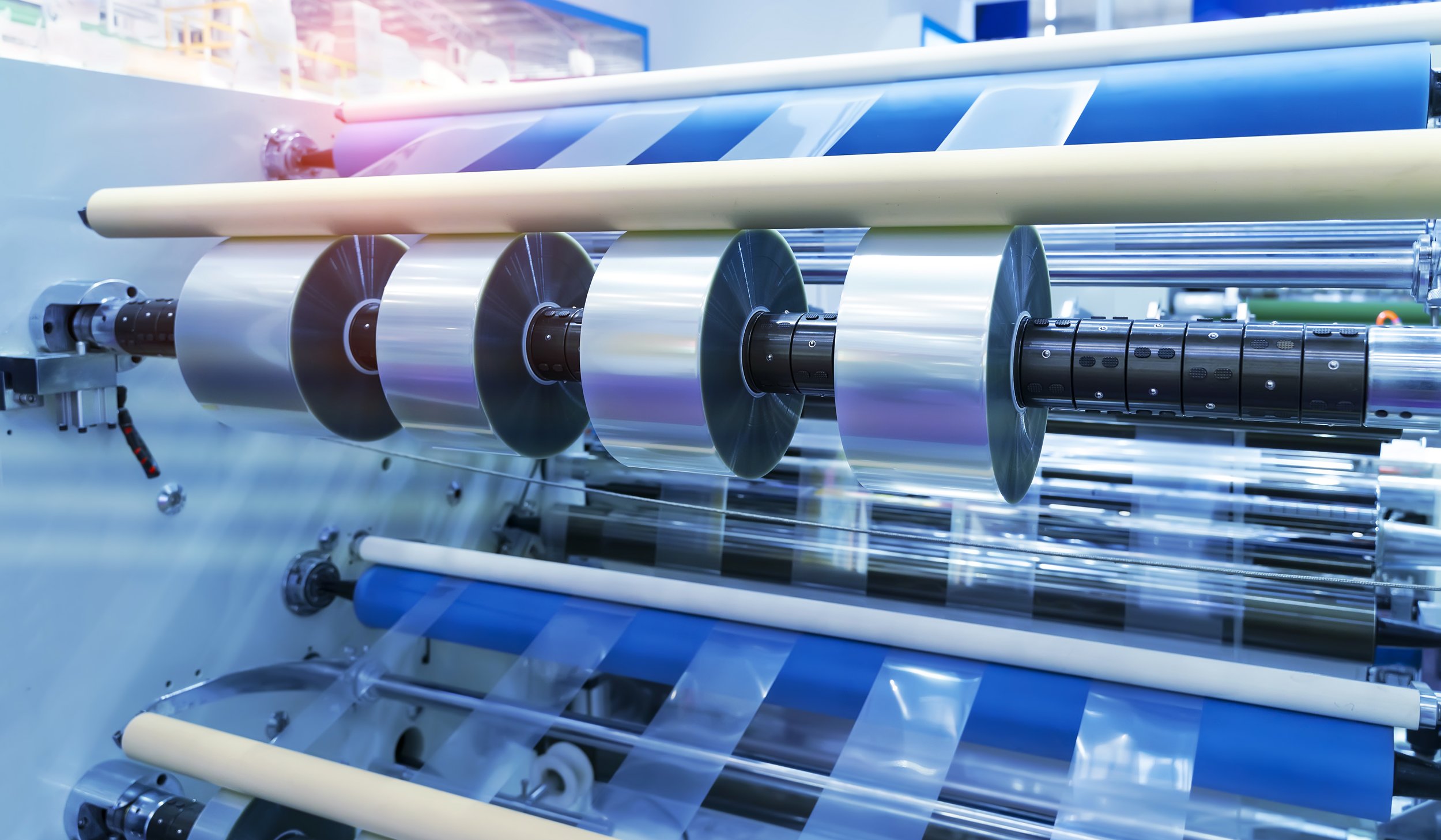

Multilayer composite films

can be used in many industries.

Maybe also in yours?

Kemp Functional Solutions focuses on

and specialises in multilayer composite films for the B2B market and is supplier of blown, extruded or cast functional special plastic films and hybrids. Here, research, development, production and consulting interact in a quality-conscious and efficient manner, so that none of your individual challenges go unsolved.

Kemp Functional Solutions develops technically and commercially optimised processes and results, primarily for industrial applications, with the help of an experienced, international team of experts in the high-tech sector – for, and above all with you. Together with our network in sales and logistics, we ensure reliable production processes and thorough quality controls.

Short distances, quick decisions

Thanks to the central European warehouse and development locations in Germany, as well as production locations in northern Italy and Benelux, we from Kemp Functional Solutions are well positioned to be able to offer small batches on large lines, as well as large orders, at short notice, quickly and reliably, and with manageable costs.

Tradition meets a spirit of research

Kemp Functional Solutions can look back on years of experience: founded in 1952 as a family business, the company has customers from all around the world. In addition to the renewable energies, infrastructure, construction, mobility, glass, SMC / BMC, ESD and GRP sectors, we are constantly looking for new challenges from different areas of work and life.

Do you have a challenge?

No problem. We from Kemp Functional Solutions are constantly looking for new challenges from different areas of work and life. Let’s get ins touch, and we’ll find a solution together.

“Our products shine with multiple special features in just one product: the multilayer composite films.”

Shape: whether flat or round

Kemp Functional Solutions is focusing on monolayer and multilayer composite films that can be readily produced using a specialised and individualised process. They are formed into tubular shapes (tubular films) or into flat shapes (flat or even calendered films) with the help of appropriate extrusion systems or blow molding machines.

Content: true allies

For hybrid films – i.e. compounds with other materials – we from Kemp Functional Solutions have the choice between lamination and polymer coating.

During the lamination process, flat joining materials such as aluminium or paper are applied to a film under pressure using adhesive powder or adhesive film. Polymer-coated materials such as textile fabrics or meshes, for example polyester or fibreglass, are coated with a polymer (PVC, TPU or TPE) during film production (extrusion coating) and then smoothed by a calender roll. They have better interlaminar properties, since the materials are fully enclosed by the polymer on both sides.

Properties: a layer seldom comes alone

Where a mono film (with only one polymer) is no longer sufficient, films from Kemp Functional Solutions make a wide range of industrial production processes possible, among other things, and shine with multiple special features in just one product: the Kemp Funtional Solutions’ multilayer composite films, which are tailored to your requirements, can consist of up to 17 different, homogeneously distributed layers with completely different thermal, mechanical and chemical properties:

Putting another on top

A final electrochemical corona treatment (on one or both sides) optimises the chemical affinity of the non-polar, electrically insulating and water-repellent film surfaces and thus allows for exemplary further processing in the form of printing or coating.

For certain applications, the films from Kemp Functional Solutions are also embossed with different textures so that optimum adhesion is possible. Hot or cold needle perforation with different patterns and hole diameters can also be readily implemented.

Only the best

The high-precision camera inspection system used by Kemp Functional Solutions, with specially developed tests, ensures optimal monitoring of our products at all times and results in our impeccable quality.

Specks of polymer which adversely affect the elasticity of films, for example, can thus be identified and winnowed out more easily.

And only for the best

Kemp Functional Solutions stands for sustainable thinking. With each project, the extent to which sustainable pro- ducts can be used is examined. The limits here arise from the profile of requirements for a desired film. It is thus possible, in the case of a 1000 µ thick calendered multilayer composite film for example, to manufacture the middle layer from recycled material alongside the other layers which must be made from virgin material.

Our producers are certified in accordance with